- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

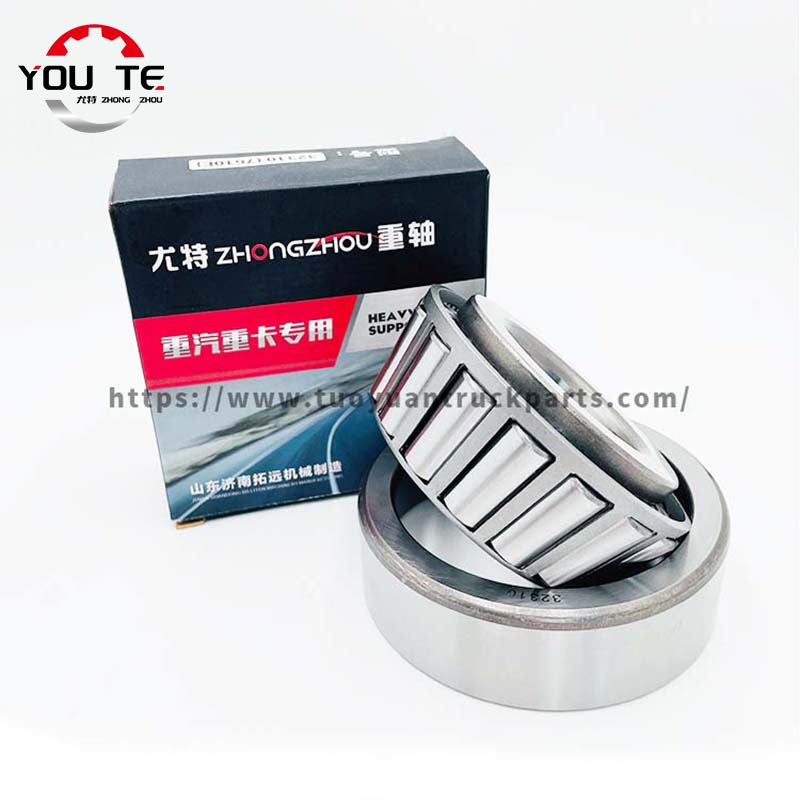

Truck Tapered Roller Bearing

As a reliable supplier and manufacturer, we offer high-quality truck tapered roller bearings that are engineered to meet the rigorous demands of the trucking industry. Our bearings are manufactured with precision and undergo rigorous quality control measures to ensure exceptional performance and reliability.

Send Inquiry

Truck Tapered Roller Bearing

Youte truck tapered roller bearing is a type of rolling element bearing that is commonly used in truck applications. It is designed to handle both radial and axial loads, providing support and smooth rotation for the truck's wheel hubs and axles.

The tapered roller bearing consists of an inner race (cone), an outer race (cup), tapered rolling elements (rollers), and a cage that holds the rollers in place. The inner race and outer race have tapered surfaces, allowing them to come into contact at a common point on the bearing axis. This design enables the bearing to handle axial (thrust) loads in addition to radial loads.

Truck tapered roller bearings are known for their high load-carrying capacity and durability. They are capable of withstanding heavy loads and extreme operating conditions often encountered in trucking and transportation applications. These bearings are designed to minimize friction and reduce heat generation, ensuring efficient and reliable performance.

Proper lubrication is crucial for the smooth operation and longevity of truck tapered roller bearings. Adequate lubrication helps reduce friction and wear, preventing premature failure of the bearing. Lubricants with high temperature and pressure resistance are commonly used in truck applications to ensure optimal performance.

When selecting a truck tapered roller bearing, factors such as load capacity, operating speed, temperature range, and service life should be considered. It is essential to choose a bearing that meets the specific requirements and regulations for the truck application.

When selecting tapered roller bearings for a gear box, factors such as load capacity, speed, operating conditions, and lubrication requirements should be considered. It is essential to choose bearings that are specifically designed and rated for gear box applications.

Product Parameter