- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

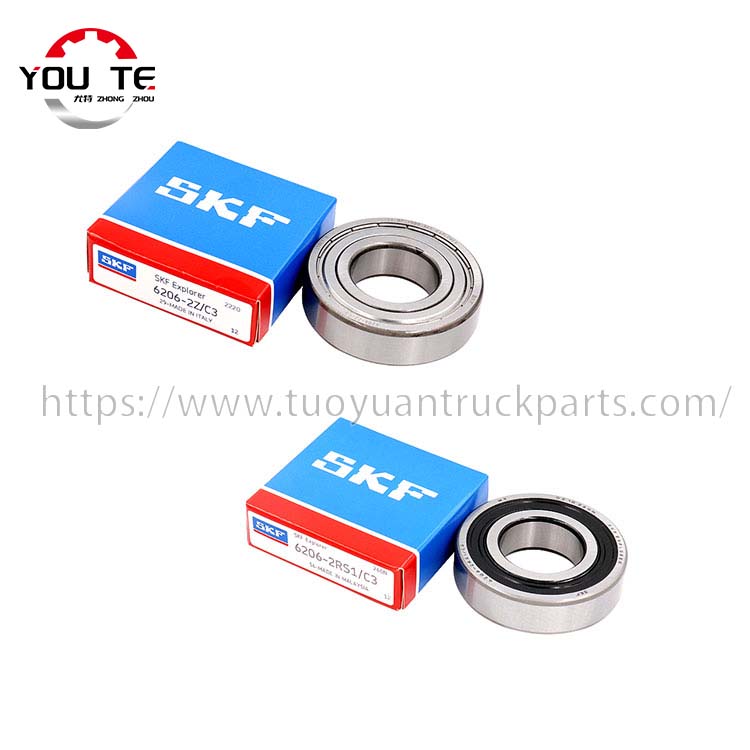

Deep Groove Ball Bearing SKF bearing

Hebei Tuoyuan Machinery Co., Ltd. specializes in selling Deep Groove Ball Bearing SKF bearing, which are the most widely used rolling bearings. It is characterized by low friction resistance and high rotation speed. It can be used on parts that bear radial loads or combined loads that act simultaneously in radial and axial directions. It can also be used on parts that bear axial loads, such as small-power motors, Automobile and tractor gearboxes, machine tool gearboxes, general machines, tools, etc.

Model:6000ZZ

Send Inquiry PDF DownLoad

Deep Groove Ball Bearing SKF bearing can be used in gearboxes, instruments, motors, household appliances, internal combustion engines, transportation vehicles, agricultural machinery, construction machinery, engineering machinery, skates, yo-yos, etc.

Deep Groove Ball Bearing SKF bearing installation method

Deep groove ball bearing installation method 1: Press fit: When the inner ring of the bearing and the shaft have a tight fit, and the outer ring and the bearing seat hole have a loose fit, you can use a press to press the bearing onto the shaft first, and then install the shaft and bearing on Together. Place them together into the bearing housing bore. When pressing in, an assembly sleeve made of soft metal material (copper or mild steel) is placed on the end face of the bearing inner ring. When the outer ring of the bearing and the bearing seat hole fit tightly, and the inner ring and the shaft fit loosely, the bearing can be pressed into the bearing seat hole first. At this time, the outer diameter of the assembly sleeve should be slightly smaller than the diameter of the seat hole. If the bearing ring, shaft and seat hole are all tightly fitted, the inner ring and outer ring should be pressed into the shaft and seat hole at the same time during installation. The structure of the assembly set should be such that the end faces of the inner and outer rings of the bearing can be trimmed at the same time.

Deep Groove Ball Bearing SKF bearing installation method 2: Heated fit: By heating the bearing or bearing seat, the installation method uses thermal expansion to transform the tight fit into a loose fit. This is a common and labor-saving installation method. This method is suitable for installation of bearings with large interference. Put the bearing or separable bearing ring into the oil tank and evenly heat it to 80-100°C before hot installation, then remove it from the oil and install it on the shaft. as soon as possible. In order to prevent the inner ring end face and shaft shoulder from cooling, if the fit is not tight, the bearing can be tightened axially after cooling. When the bearing outer ring is tightly matched with the light metal bearing seat, the hot fitting method of heating the bearing seat can avoid scratches on the mating surface. When using an oil tank to heat the bearings, there should be a grid at a certain distance from the bottom of the oil tank, or a hook should be used to hang the bearings. The bearing cannot be placed at the bottom of the groove to prevent impurities from entering the bearing or uneven heating. There must be a thermometer in the tank. Strictly control the oil temperature not to exceed 100°C to prevent tempering effects and reduce ferrule hardness.

| Name |

Deep Groove Ball Bearing SKF bearing |

| Model |

6000ZZ |

| MOQ | 100 PCS |