- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

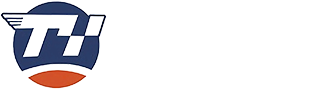

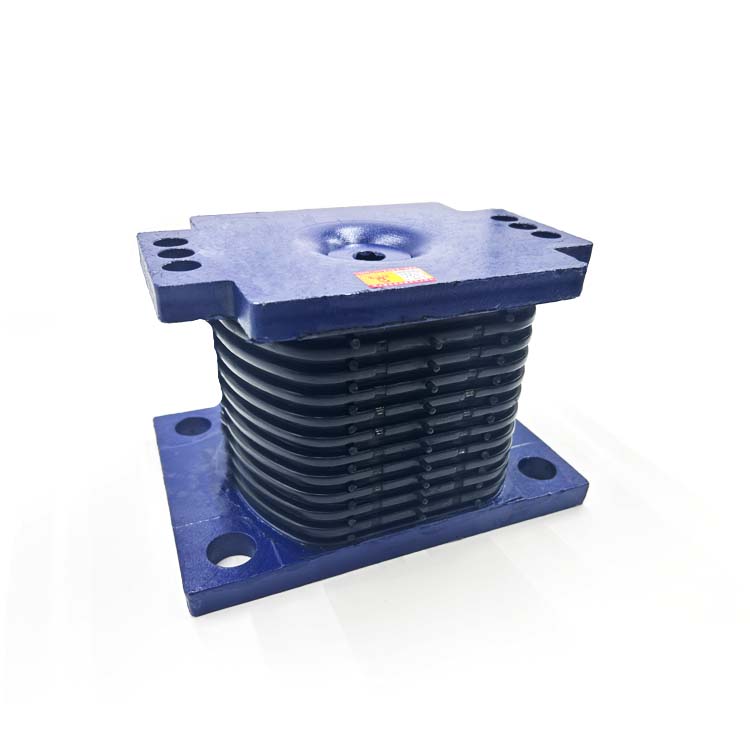

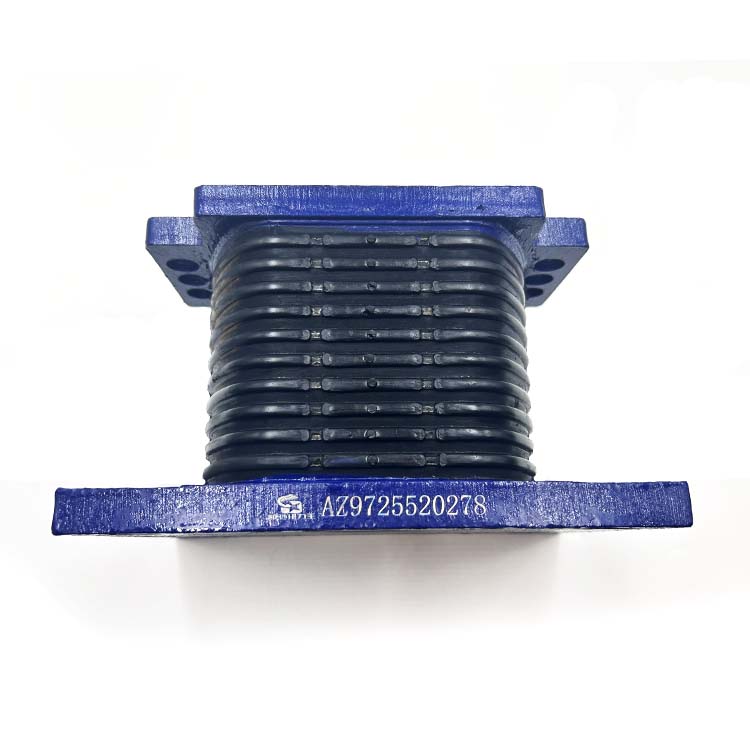

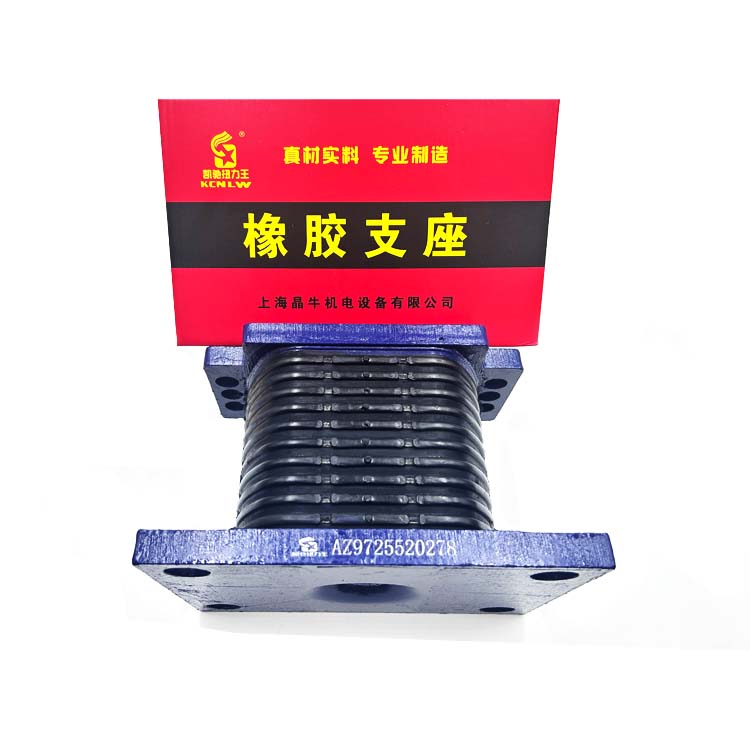

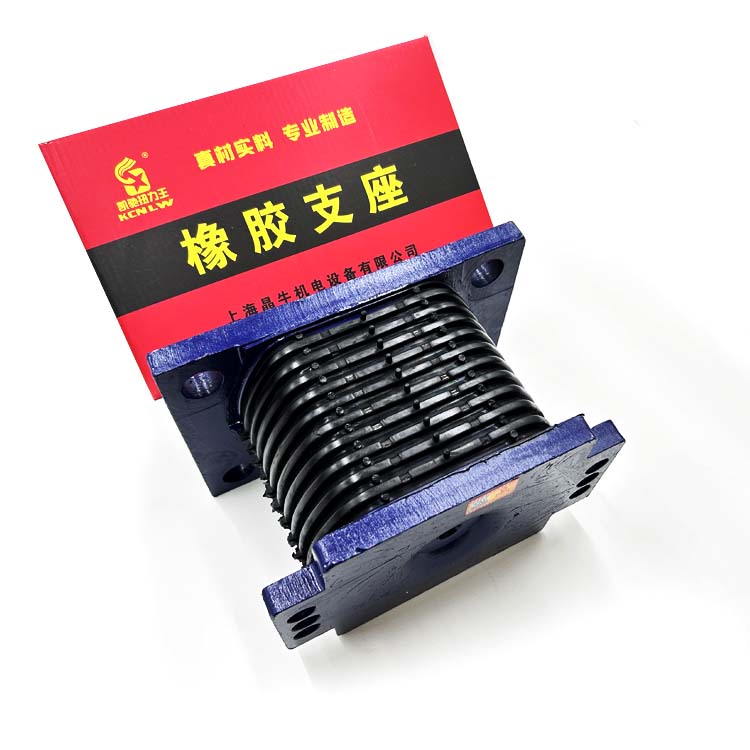

Truck Rubber Leaf Spring Mounting For SITRAK

The English name Truck Rubber Leaf Spring Mounting For SITRAK of the chassis bridge of SINOTRUK to play the role of shock absorption and buffering. The torque rubber core is basically assembled from outer jacket + inner sleeve + bottom bracket + rubber/nylon/polyurethane + nylon bowl + snap ring + dust cover and other materials.

Model:AZ9925522175

Send Inquiry

The laminated Truck Rubber Leaf Spring Mounting For SITRAK is composed of a steel plate and a rubber layer. The steel plate has good vertical compression resistance and the rubber layer has good horizontal deformation ability. The two are combined through a vulcanization process to make the laminated rubber bearing At the same time, it has the function of bearing the vertical load and horizontal displacement of the building.

The structure of laminated Truck Rubber Leaf Spring Mounting For SITRAK is also divided into lead core type and lead-free core type. The lead-free core type is composed of steel plate and laminated rubber. The lead core type (lead core rubber bearing) is a cylindrical lead core set in a multi-layer rubber bearing. When the bearing is sheared and deformed, the lead core absorbs energy through plastic deformation. The lead core relies on itself to recrystallize and recover at room temperature. Mechanical properties of the Truck Rubber Leaf Spring Mounting For SITRAK.

| Model |

AZ9925522175 |

| Name |

Truck Rubber Leaf Spring Mounting For SITRAK |

| MOQ | 1 PCS |