- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

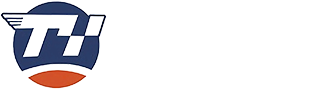

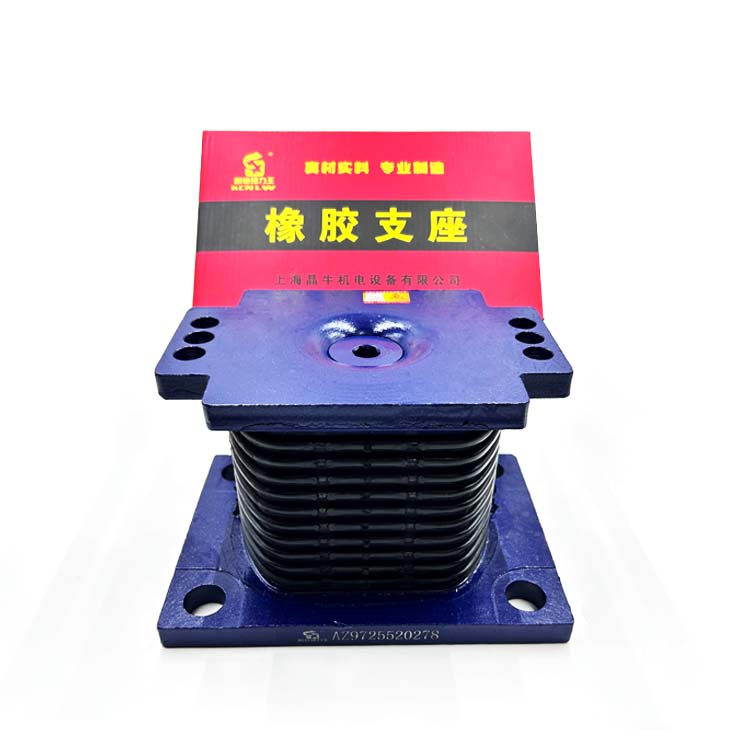

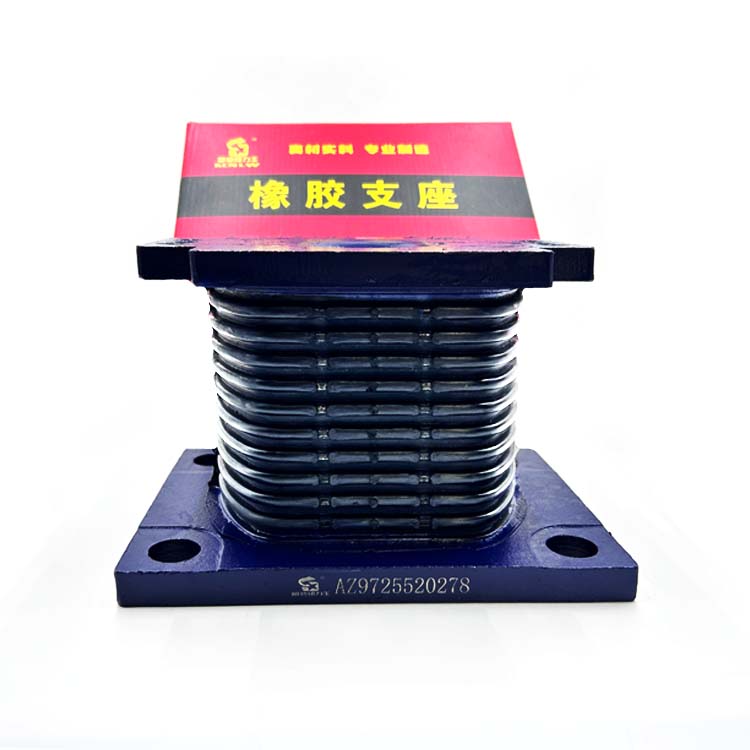

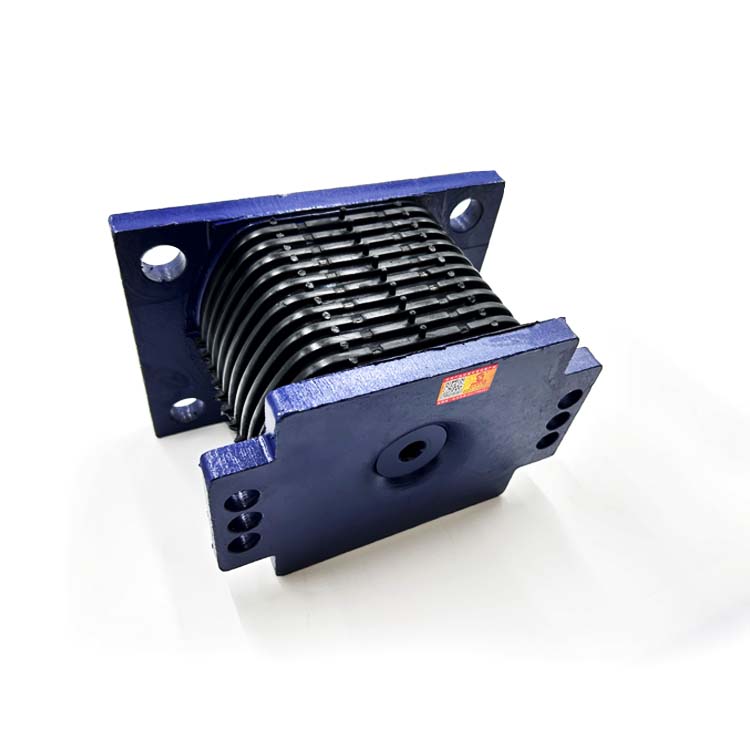

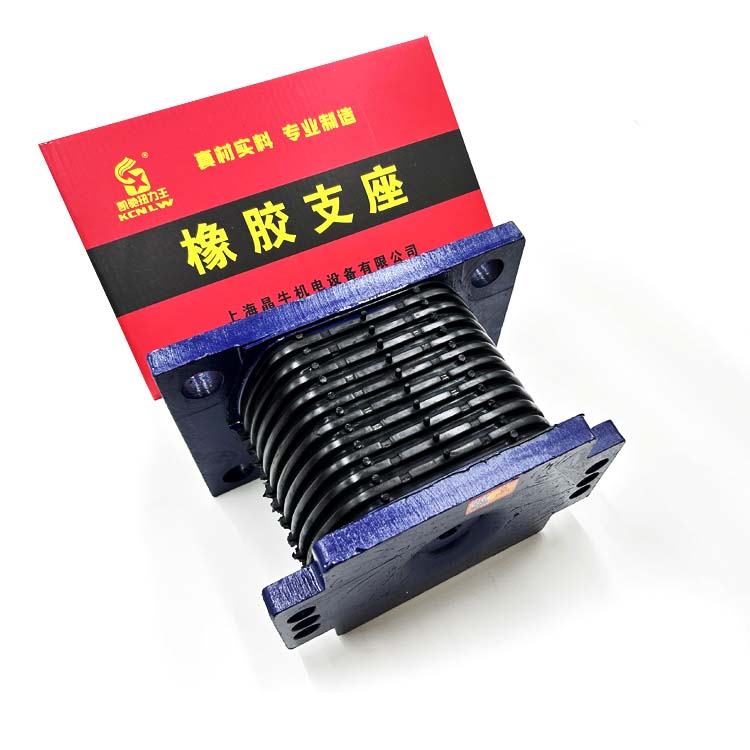

Truck Rubber Leaf Spring Mounting For Ten Layers Of Rubber

Truck Rubber Leaf Spring Mounting For Ten Layers Of Rubber is a bridge bearing product made of multiple layers of natural rubber and thin steel plates inlaid, bonded and vulcanized. This type of rubber bearing has sufficient vertical stiffness to withstand vertical loads and can reliably transmit the pressure of the superstructure to the pier; it has good elasticity to adapt to the rotation of the beam end; it has large shear deformation to satisfy the horizontal displacement of the superstructure.

Model:AZ9725520274

Send Inquiry

The correct positioning of theTruck Rubber Leaf Spring Mounting For Ten Layers Of Rubber must first ensure that the bearing and supporting pad are accurately positioned according to the design requirements. When erecting and lowering beams, the longitudinal axis of the T-shaped beam should coincide with the center line of the support; the longitudinal axis of the plate beam and box beam should be parallel to the center line of the support. In order to accurately drop the beam, when erecting the first span plate beam or box beam, the cross position center of the two supports can be marked on the bottom of the beam, and the position center line of the two supports can be marked on the end elevation of the beam. The plumb line shall coincide with the center line of the pier when the beam is dropped.

The next few spans can be carried out based on the first span beam. When erecting and lowering the beam, it must be stable to prevent deflection or initial shear deformation. You can refer to the specification table of railway bridge plate rubber bearings. When installing a T-shaped bridge, if the rubber bearing is wider than the bottom of the beam reinforcement, a reinforced concrete block or a thick steel plate larger than the bearing should be added as a transition layer between the bearing and the bottom of the beam reinforcement to prevent the bearing from being partially Pressure causes stress concentration.

Reinforced concrete pads or thick steel plates should be bonded to the bottom of the beam bars with epoxy resin mortar. After the beam is dropped, the top surface of the Truck Rubber Leaf Spring Mounting For Ten Layers Of Rubberand the beam surface are generally kept level. For prestressed simply supported beams, the top surface of the support can be tilted later; for non-prestressed beams, the top surface of the support can be slightly tilted forward, but the tilt angle must not exceed 5".

| Model |

AZ9725520274 |

| Name |

Truck Rubber Leaf Spring Mounting For Ten Layers Of Rubber |

| moq | 1 pcs |